[ad_1]

Hold a cold drink on a hot day, and watch as small droplets form on the glass, eventually coalescing into a layer of moisture (and prompting you to reach for a coaster).

This basic physical process, condensation, is what refrigerators and air conditioners use to remove heat from vapor by turning it into a liquid. Just like the cold glass, the surfaces of metal condensers form thin layers of moisture as they work.

And that’s a problem. The liquid layer acts as a thermally resistant barrier between the warm vapor and the cold condenser surface, decreasing the condenser’s heat transfer efficiency. Ideally, the droplets on the condenser, instead of coalescing, would simply bead up and move away, making way for more vapor to contact the condenser and turn into liquid.

Materials scientists at Colorado State University have spent time thinking about this problem. They’ve published the fundamental physics of a possible solution in the journal Science Advances. Their new strategy could potentially increase the efficiency of condensers, used in many domestic and industrial products.

A team led by Arun Kota, assistant professor in mechanical engineering and the School of Biomedical Engineering, has figured out how to keep condensed droplets from coalescing into a film, and to make the droplets jump high enough to move away from the condenser surface.

“We believe that our strategy has the potential to enable next-generation condensers with improved efficiency,” Kota said. “Our strategy is simple, power-free and scalable.” The experiments and numerical simulations were carried out by the paper’s co-first authors: CSU graduate student Hamed Vahabi and postdoctoral researcher Wei Wang.

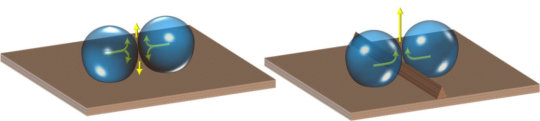

Their solution is a combination of creativity, chemistry and physics, along with Kota’s lab’s extensive research in “superomniphobic” surfaces that repel many different kinds of liquids. The researchers worked out the physics of using a superomniphobic surface with knife-like ridges to form these jumping droplets.

When droplets coalesce on these superomniphobic ridges, the ridge architecture causes the new, larger droplet to jump away with significantly higher kinetic energy compared to surfaces with no ridge architecture. The researchers envision that condensers dotted with such superomniphobic ridges can remove condensed droplets more efficiently, leading to higher heat transfer efficiency.

Other researchers have demonstrated the ability to make droplets jump this way, but the CSU work is set apart by combining the superomniphobic surface with the specific ridge architecture. Furthermore, they made the jumping-droplet phenomenon work with a wide range of liquids, including those with low surface tensions and high viscosities. They’ve also shown that the concept works at many sizes, from macroscopic down to micron length scales and potentially even sub-micron length scales.

Story Source:

Materials provided by Colorado State University. Note: Content may be edited for style and length.

[ad_2]