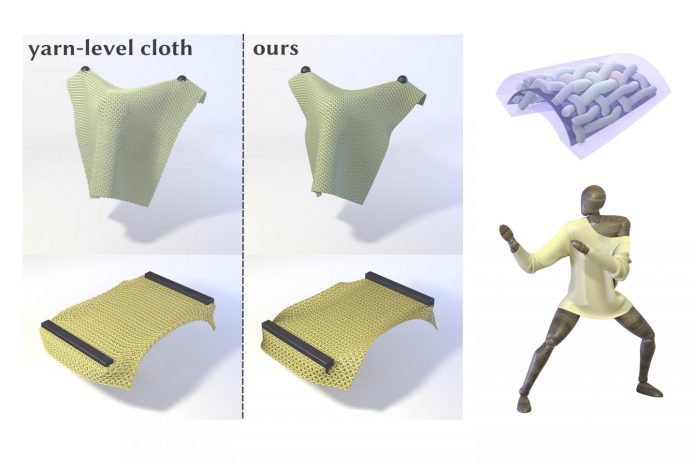

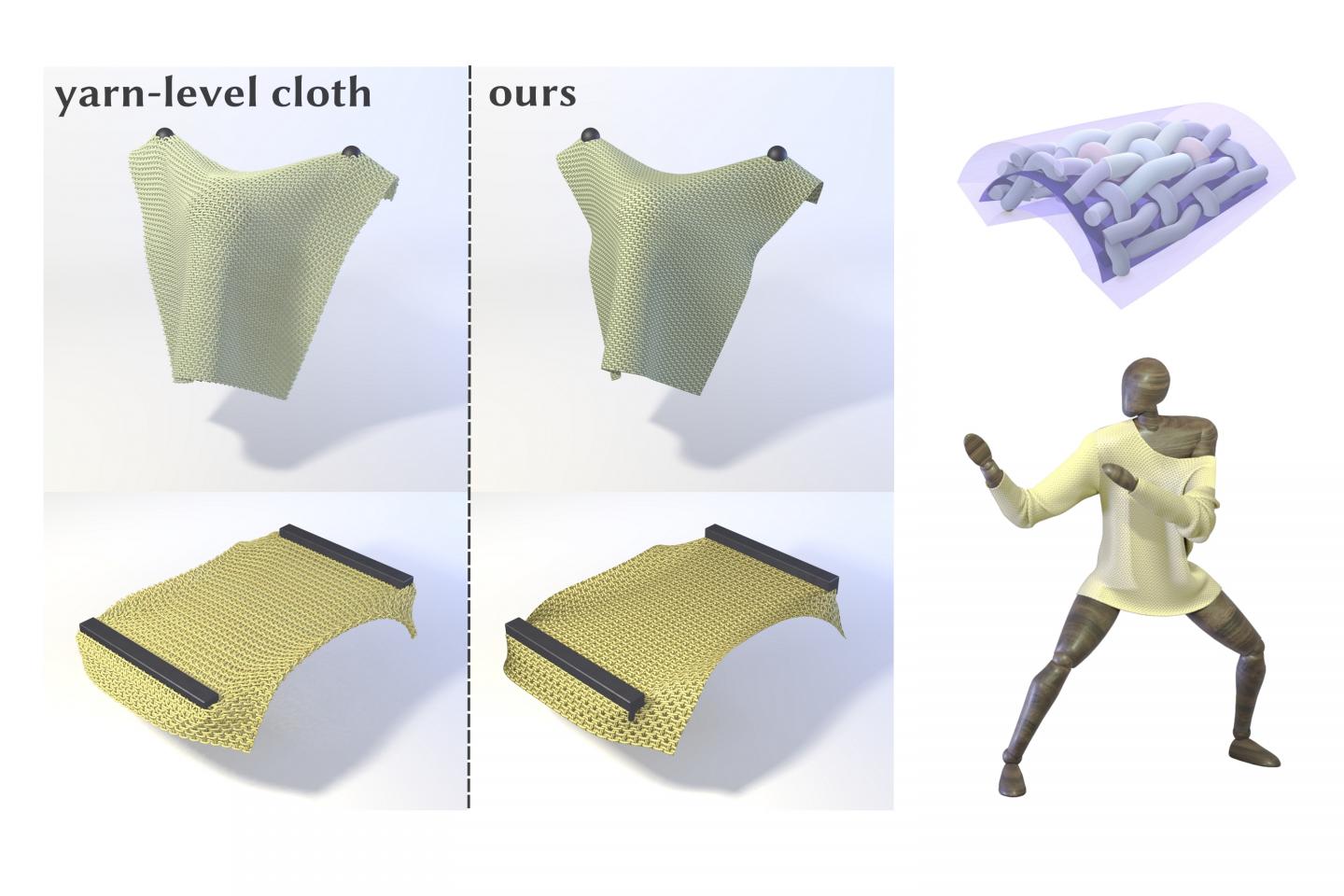

IMAGE: A team will present a method for animating yarn-level cloth effects using a thin-shell solver. The new method will be presented at ACM SIGGRAPH 2020.

view more

Credit: © Georg Sperl, Rahul Narain, and Chris Wojtan

The simulation of woven and knitted fabrics is an ongoing problem in computer graphics. Simulating the way a fabric drapes or moves while being worn, while accurately modeling low-level effects such as the stiffness and stretch of individual yarns, is a complicated challenge that requires sophisticated computational modeling.

In this new work, a global team of computer scientists from the Institute of Science and Technology (IST) Austria and Indian institute of Technology Delhi (IITD) has developed a method for specifically animating yarn-level cloth effects, accurately capturing the physics of the material, including the stretching and bending response. The results of the team’s homogenized computational modeling framework accurately mimic the appearance of knitted and woven materials using yarn.

The team, comprised of Georg Sperl and Chris Wojtan from IST Austria and Rahul Narain from IITD, is set to present their work at SIGGRAPH 2020. The conference, which will take place virtually this year starting 17 August, gathers a diverse network of professionals who approach computer graphics and interactive techniques from different perspectives. SIGGRAPH continues to serve as the industry’s premier venue for showcasing forward-thinking ideas and research.

“Yarn-level cloth techniques produce beautifully detailed and realistic results, but it can become impractically slow to simulate full garments,” Sperl, lead author of the research and Ph.D. student in the Wojtan lab at IST Austria, says. “Our method helps make such simulations more feasible by precomputing the mechanical properties of yarn patterns and fitting continuum materials that can be used in existing mesh-based simulators. This can greatly speed up the simulation of cloth while preserving the material’s overall stretching and bending resistance and capturing characteristic phenomena of fabrics such as curling.”

Picture the level of details that make up yarn cloth, from a variety of lengths and widths, the various appearances of spun thread, and the wide array of patterns created with yarn cloth by knitting, crocheting, or weaving. The team’s approach is able to capture all of these specific details and material properties of yarn-level cloth in a truly realistic and precise way.

They validated their method using stretching and draping tests that produced accurate translations of the fabric in a virtual world. Visual examples included the animation of a variety of detailed yarn-cloth patterns and techniques, i.e., slip stitch honeycomb and satin weave, showcasing more of the folds, curling, and wrinkles of the cloth while draped over an object or worn as a sweater or scarf.

One of the important challenges the team addressed was the ability to simulate yarn-level cloth faster and at scale. Their method captures the complex physics emerging from yarn patterns at a fraction of the cost of direct yarn-level cloth simulation.

“Our technique allows us to capture the resistance of multiple deformations at the same time,” the authors say. “We additionally developed a procedure to fit a material model capable of capturing these effects from homogenized data. With this, we were able to automatically reproduce characteristic behaviors of different fabrics, including subtle phenomena like the interaction between stretching and curling in knitted patterns, which have not been captured in previous cloth models.”

In the future, this method could expand to animate other complicated multi-physics materials like layered quilts, layered elastic material, skin tissue, and deployable shells. The team’s method opens up exciting avenues for future studies by applying it to homogenization of layered or composite materials, for estimating material properties of new materials constructed from simpler components, or for inverse design problems in the manufacturing of knitted cloth.

###

TDnews