[ad_1]

Ceramic materials are used in nuclear, chemical and electrical power generation industries because of their ability to withstand extreme environments. However, at high temperatures, ceramics are susceptible to thermal-shock fractures caused by rapid temperature-changing events, such as cold water droplet contact with hot surfaces. In a novel interdisciplinary approach, engineers at the University of New Mexico report in AIP Advances, from AIP Publishing, the use of a cheap, simple, water-repelling coating to prevent thermal shock in ceramics.

“We use exactly the same material but control the heat transfer, allowing the material to see a more benign temperature gradient, alleviating tensile stresses and so radically improving thermal shock behavior,” said Youho Lee, at the University of New Mexico and one of the authors of the paper.

Thermal shock is a phenomenon often experienced in the kitchen by novice cooks unaware of the susceptibility of glass to dramatic temperature changes. If a glass casserole dish fresh from the heat of the oven is blasted with cold water, the sudden decrease in surface temperature creates an uneven temperature gradient across the material, causing tensile stresses and ultimately cracks. This same thermal-shock susceptibility impacts the lifetime of industrial ceramics.

Lee explained that in previous attempts to improve thermal-shock resistance, materials scientists changed properties of the material itself, but this is an expensive and difficult process with inherent drawbacks. “If you improve the material in one way, you sacrifice other properties,” Lee said.

From his interdisciplinary academic background, Lee had experience investigating heat transfer and so he decided to explore the effect of heat transfer on ceramic thermal shock.

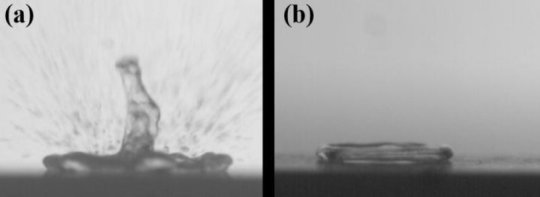

Heat transfer was examined by taking high-speed videos of water droplet impact upon a heated ceramic surface. “When heat transfer is fast, the collision moments are characterized by violent bubbles and jets on the surface,” Lee said. And, these faster heat-transfer modes were found to correspond to a reduction in material strength, as assessed in bending tests. A greater reduction in material strength was found when the ceramic was heated up to 325 degrees Celsius, with correspondingly more dramatic droplet dynamics, indicating faster heat transfer. However, at temperatures higher than 325 C, material strength appeared less affected by heat shock, and droplet dynamics changed to form an appreciable vapor film.

To reduce the heat transfer, and hence thermal shock experienced by ceramics at temperatures ranging up to 325 C, Lee used some nuclear engineering know-how — that is, a two-phase heat-transfer rate can be reduced by repelling water from the surface to form an insulating vapor film. Therefore, he coated the ceramic surface with nanoparticles, creating a nanostructured, hydrophobic surface. When experiments were repeated on the newly coated ceramic material, droplet dynamics were dramatically changed, with no violent jets of bubbles; instead, vapor film formation was observed. Crucially, the coated ceramics exhibited no alteration in strength after droplet impingement.

“What we did was very simple, with no expensive, fancy equipment or materials,” Lee said. “The innovation of this study was to prevent dramatic heat transfer by promoting the vapor film formation, which insulated the material from thermal shock.”

From his nuclear engineering perspective, Lee envisions that these findings can be used to improve nuclear power plant safety by increasing the thermal-shock tolerance of nuclear components. But this insulating coating is not limited to nuclear applications and can be applied to any ceramic material used in industries operating at high temperatures.

Lee also sees an additional benefit from the correlation between heat-transfer mode and material ceramic strength change, and thinks that this ceramic “memory” could be used in heat-transfer detection. “In many engineering applications it is hard to install a high-speed video camera to assess heat transfer,” Lee said. “However, you can use a ceramic material for an application that, for instance, requires a high-pressure chamber; its strength afterward can be used as a measure of heat transfer.”

Story Source:

Materials provided by American Institute of Physics. Note: Content may be edited for style and length.

[ad_2]