[ad_1]

Living organisms expand and contract soft tissues to achieve complex, 3-D movements and functions, but replicating those movements with human-made materials has proven challenging.

A University of Texas at Arlington researcher recently published groundbreaking research in Nature Communications that shows promise in finding a solution.

Kyungsuk Yum, an assistant professor in UTA’s Materials Science and Engineering Department, and his doctoral student, Amirali Nojoomi, have developed a process by which 2-D hydrogels can be programmed to expand and shrink in a space- and time-controlled way that applies force to their surfaces, enabling the formation of complex 3-D shapes and motions.

This process could potentially transform the way soft engineering systems or devices are designed and fabricated. Potential applications for the technology include bioinspired soft robotics, artificial muscles — which are soft materials that change their shapes or move in response to external signals as our muscles do — and programmable matter. The concept is also applicable to other programmable materials.

“We studied how biological organisms use continuously deformable soft tissues such as muscle to make shapes, change shape and move because we were interested in using this type of method to create dynamic 3-D structures,” Yum said.

His approach uses temperature-responsive hydrogels with local degrees and rates of swelling and shrinking. Those properties allow Yum to spatially program how the hydrogels swell or shrink in response to temperature change using a digital light 4-D printing method he developed that includes three dimensions plus time.

Using this method, Yum can print multiple 3-D structures simultaneously in a one-step process. Then, he mathematically programs the structures’ shrinking and swelling to form 3-D shapes, such as saddle shapes, wrinkles and cones, and their direction.

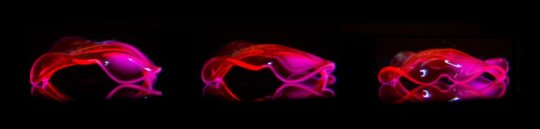

He also has developed design rules based on the concept of modularity to create even more complex structures, including bioinspired structures with programmed sequential motions. This makes the shapes dynamic so they can move through space. He also can control the speed at which the structures change shape and thus create complex, sequential motion, such as how a stingray swims in the ocean.

“Unlike traditional additive manufacturing, our digital light 4-D printing method allows us to print multiple, custom-designed 3-D structures simultaneously. Most importantly, our method is very fast, taking less than 60 seconds to print, and thus highly scalable.”

“Dr. Yum’s approach to creating programmable 3D structures has the potential to open many new avenues in bioinspired robotics and tissue engineering. The speed with which his approach can be applied, as well as its scalability, makes it a unique tool for future research and applications,” Meletis said.

Story Source:

Materials provided by University of Texas at Arlington. Original written by Jeremy Agor. Note: Content may be edited for style and length.

[ad_2]