[ad_1]

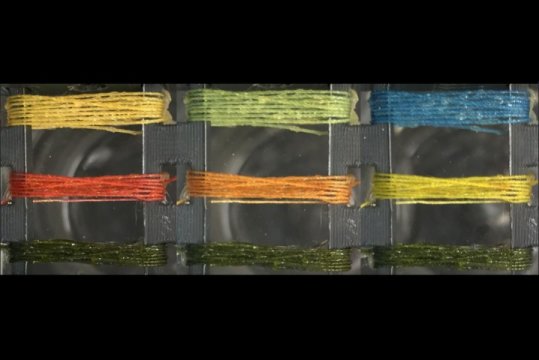

Tufts University engineers have developed a novel fabrication method to create dyed threads that change color when they detect a variety of gases. The researchers demonstrated that the threads can be read visually, or even more precisely by use of a smartphone camera, to detect changes of color due to analytes as low as 50 parts per million. Woven into clothing, smart, gas-detecting threads could provide a reusable, washable, and affordable safety asset in medical, workplace, military and rescue environments, they say. The study, published today in the journal Scientific Reports, describes the fabrication method and its ability to extend to a wide range of dyes and detection of complex gas mixtures.

While not replacing the precision of electronic devices commonly used to detect volatile gases, incorporation of gas detection into textiles enables an equipment-free readout, without the need for specialized training, the researchers say. Such an approach could make the technology accessible to a general workforce, or to low resource communities that can benefit from the information the textiles provide.

The study used a manganese-based dye, MnTPP, methyl red, and bromothymol blue to prove the concept. MnTPP and bromothymol blue can detect ammonia while methyl red can detect hydrogen chloride — gases commonly released from cleaning supplies, fertilizer and chemical and materials production. A three-step process “traps” the dye in the thread. The thread is first dipped in the dye, then treated with acetic acid, which makes the surface coarser and swells the fiber, possibly allowing more binding interactions between the dye and tread. Finally, the thread is treated with polydimethylsiloxane (PDMS), which creates a flexible, physical seal around the thread and dye, which also repels water and prevents dye from leaching during washing. Importantly, the PDMS is also gas permeable, allowing the analytes to reach the optical dyes.

“The dyes we used work in different ways, so we can detect gases with different chemistries,” said Sameer Sonkusale, professor of electrical and computer engineering at Tufts University’s School of Engineering who heads the Nano Lab at Tufts and is corresponding author of the study. Sonkusale’s team used simple dyes that detect gases with acid or base properties. “But since we are using a method that effectively traps the dye to the thread, rather than relying so much on binding chemistry, we have more flexibility to use dyes with a wide range of functional chemistries to detect different types of gases,” he said.

The tested dyes changed color in a way that is dependent and proportional to the concentration of the gas as measured using spectroscopic methods. In between the precision of a spectrometer and the human eye is the possibility of using smart phones to read out and quantify the color changes or interpret color signatures using multiple threads and dyes. “That would allow us to scale up the detection to measure many analytes at once, or to distinguish analytes with unique colorimetric signatures,” said Sonkusale.

The threads even worked under water, detecting the existence of dissolved ammonia. “While the PDMS sealant is hydrophobic and keeps water off the thread, the dissolved gases can still reach the dye to be quantified.” said Rachel Owyeung, lead author and graduate student in the Tufts Department of Chemical and Biological Engineering. “As dissolved gas sensors, we imagine smart fabrics detecting carbon dioxide or other volatile organic compounds during oil and gas exploration as one possible application.”

Since repeated washing or use underwater does not dilute the dye, the threads can be relied upon for consistent quantifiable detection many times over, the researchers said.

Story Source:

Materials provided by Tufts University. Note: Content may be edited for style and length.

[ad_2]