Production of high-energy fats by microalgae may provide a sustainable, renewable energy source that can help tackle climate change. However, microalgae engineered to produce lipids rapidly usually grow slowly themselves, making it difficult to increase overall yields.

UCLA bioengineers have created a new type of petri dish in the form of microscopic, permeable particles that can dramatically speed up research and development (R&D) timelines of biological products, such as fatty acids for biofuels. Dubbed PicoShells, the picoliter (trillionth of a liter), porous, hydrogel particles can enable more than one million individual cells to be compartmentalized, cultured in production-relevant environments, and selected based on growth and biomass accumulation traits using standard cell-processing equipment.

Proceedings of the National Academy of Sciences recently published a study detailing how PicoShells work and their potential applications.

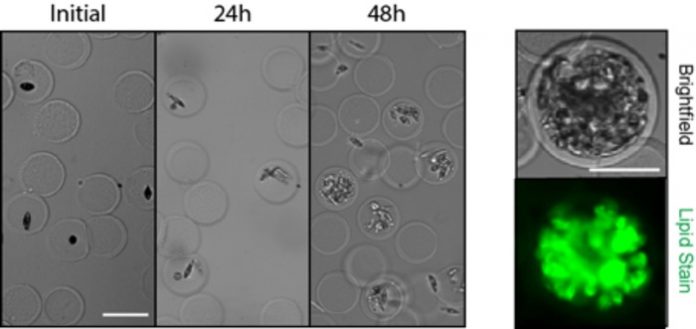

PicoShells consist of a hollow inner cavity where cells are encapsulated and a porous outer shell that allows for continuous solution exchange with the external environment so that nutrients, cell-communication molecules and cytotoxic cellular byproducts can transport freely in and out of the inner cavity. The shell also keeps the small groups of growing cells penned in, allowing researchers to study and compare their behaviors — what they do, how fast they grow, what they produce — to those of other groups inside various PicoShells.

This new class of lab tool allows researchers to grow living, single-cell microorganisms — including algae, fungi and bacteria — under the same industrial-production conditions, such as in a bioreactor filled with wastewater or an outdoor cultivation pond.

“PicoShells are like very tiny mesh balloons. The growing cells inside them are effectively fenced in but not sealed off,” said study leader Dino Di Carlo, UCLA’s Armond and Elena Hairapetian Professor in Engineering and Medicine at the UCLA Samueli School of Engineering. “With this new tool, we can now study the individual behaviors of millions of living cells in the relevant environment. This could shorten R&D-to-commercial production timelines for bioproducts from a few years to a few months. PicoShells could also be a valuable tool for fundamental biology studies.”

PicoShells’ permeability can bring the lab to the industrial environment, allowing testing at a sectioned-off area of a working facility. Growth can occur more quickly and cell strains that perform well can be identified and selected for further screening.

According to the researchers, another advantage of this new tool is that the analysis of millions of PicoShells is automated since they are also compatible with standard lab equipment used for high-volume cell processing.

Massive groups of cells, up to 10 million in one day, can be sorted and organized by certain characteristics. Continuous analysis could result in ideal sets of cells — ones that are already performing well in the environment with suitable temperature, nutrient composition and other properties that could be used in mass production — in just a few days rather than the several months it would take using current technologies.

The shells can be engineered to burst when the cells inside have divided and grown beyond their peak volume. Those free cells are still viable and can be recaptured for continued research or further selection. The researchers can also create shells with chemical groups that break down when exposed to biocompatible reagent, enabling a multifaceted approach to release selected cells.

“If we want to zero in on algae that are the best at producing biofuels, we can use PicoShells to organize, grow and process millions of single algal cells,” said lead author Mark van Zee, a bioengineering graduate student at UCLA Samueli. “And we can do that in machines that sort them using fluorescent tags that light up to signify fuel levels.”

Currently, cultivating and comparing such microorganisms are done mostly using traditional lab tools, such as microwell plates — cartons that hold several dozen small test tube-like volumes. However, these methods are slow and it is difficult to quantify their effectiveness because it can take weeks or months to grow large colonies for study. Other approaches, such as water-in-oil droplet emulsions, can be used to analyze cells in smaller volumes, but surrounding oils prevent the free exchange of medium into the water drops. Even cells or microorganisms that perform well in lab conditions may not do as well once they are placed in industrial environments, such as bioreactors or outdoor cultivation farms. As a result, cell strains that are developed in the lab often do not exhibit the same beneficial characteristic behavior when transferred to industrial production.

Microwell plates also are limited in the number of experiments that can be performed, resulting in a great deal of trial and error in finding cell strains that work sufficiently well for mass production.

The researchers demonstrated the new tool by growing colonies of algae and yeast, comparing their growth and viability against other colonies grown in water-in-oil emulsions. For the algae, the team found that PicoShell colonies accumulated biomass rapidly while algae did not grow at all in water-in-oil emulsions. Similar results were found in their yeast experiments. By selecting the top growing algae in PicoShells, the researchers could increase the production of chlorophyll biomass by 8% after only a single cycle.

The authors said PicoShells could offer a faster alternative to develop new algae and yeast strains, leading to improved biofuels, plastics, carbon-capture materials and even food products and alcoholic beverages. Further refinements to the technology, such as coating the shells with antibodies, could also lead to developing new types of protein-based medicines.

Di Carlo, van Zee and study co-author Joseph de Rutte Ph.D. ’20, a former member of Di Carlo’s research group, are named inventors on a patent application filed by the UCLA Technology Development Group.

The other UCLA authors on the paper are Rose Rumyan, Cayden Williamson, Trevor Burnes, Andrew Sonico Eugenio, Sara Badih, Dong-Hyun Lee and Maani Archang. Randor Radakovits from Synthetic Genomics of San Diego is also an author.

The study was supported by the Presidential Early Career Award for Scientists and Engineers and a planning award from the California NanoSystems Institute (CNSI) at UCLA.

Di Carlo holds faculty appointments in bioengineering, and mechanical and aerospace engineering at UCLA Samueli. He is a member of CNSI and the Jonsson Comprehensive Cancer Center at UCLA.