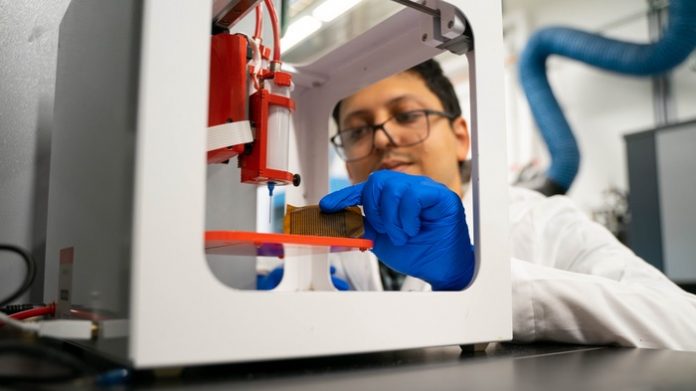

The creation of high-resolution extrusion printing—think 3D printing but with ink that conducts electricity—has enabled UBC researchers to explore the potential of wearable human motion devices.

Wearable technology—smartwatches, heart monitors, sleep aid devices, even step counters—have become part of everyday life. And researchers with UBC Okanagan’s Nanomaterials and Polymer Nanocomposites Laboratory, have created even smaller, lighter and highly-accurate sensors that can be integrated into clothing and equipment.

In collaboration with Drexel University and the University of Toronto, the UBCO research team is exploring a high-resolution extrusion printing approach to develop tiny devices with dual functionality—electromagnetic interference (EMI) shields and a body motion sensor.

Tiny and lightweight, these EMI shields can have applications in the health care, aerospace and automotive industries, explains Dr. Mohammad Arjmand, Assistant Professor and Canada Research Chair in Advanced Materials and Polymer Engineering at UBC Okanagan’s School of Engineering.

Using a two-dimensional inorganic nanomaterial called MXene, alongside a conductive polymer, Dr. Arjmand’s team has customized a conductive ink with a number of properties that make it easier to adapt into wearable technologies.

“Advanced or smart materials that provide electrical conductivity and flexibility are highly sought-after,” he says. “Extrusion printing of these conductive materials will allow for macro-scale patterning, meaning we can produce different shapes or geometries, and the product will have outstanding architecture flexibility.”

Currently, manufacturing technologies of these functional materials are mostly limited to laminated and unsophisticated structures that don’t enable the integration of monitoring technologies, explains doctoral student Ahmadreza Ghaffarkhah.

“These printed structures can be seeded with micro-cracks to develop highly sensitive sensors. Tiny cracks in their structures are used to track small vibrations in their surroundings,” says Ghaffarkhah. “These vibrations can monitor a multitude of human activities, including breathing, facial movements, talking as well as the contraction and relaxation of a muscle.”

By going back to the drawing board, the UBCO researchers were able to address a major challenge encountered by extrusion printing. Previously, the technology didn’t allow for high-enough printing resolution, so it was difficult to manufacture highly precise structures.

“Compared to conventional manufacturing technologies, extrusion printing offers customization, reduction in materials waste, and rapid production, while opening up numerous opportunities for wearable and smart electronics,” explains Dr. Arjmand. “As extrusion printing techniques improve, it is opening the door to many unique innovations.”

The researchers continue to investigate additional applications for extrusion printing inks that go beyond EMI shields and wearable electronics.