[ad_1]

Icy weather is blamed for multibillion dollar losses every year in the United States, including delays and damage related to air travel, infrastructure and power generation and transmission facilities. Finding effective, durable and environmentally stable de-icing materials has been stymied by the stubborn tenacity with which ice adheres to the materials on which it forms.

Researchers from the University of Houston have reported a new theory in physics called stress localization, which they used to tune and predict the properties of new materials. Based on those predictions, the researchers reported in Materials Horizons that they have created a durable silicone polymer coating capable of repelling ice from any surface.

“We have developed a new physical concept and the corresponding icephobic material that shows extremely low ice adhesion while having long-term mechanical, chemical and environmental durability,” they wrote.

Hadi Ghasemi, Bill D. Cook Assistant Professor of mechanical engineering at UH and corresponding author for the work, said the findings suggest a way to take trial and error out of the search for new materials, in keeping with the movement of materials science toward a physics-driven approach.

“You put in the properties you want, and the principle will tell you what material you need to synthesize,” he said, noting that the concept can also be used to predict materials with superb antibacterial or other desirable properties.

His collaborators on the project include Payman Irajizad, Abdullah Al-Bayati, Bahareh Eslami, Taha Shafquat, Masoumeh Nazari, Parham Jafari, Varun Kashyap and Ali Masoudi, all with the UH Department of Mechanical Engineering, and Daniel Araya, a former UH faculty member who is now at the Johns Hopkins University Applied Physics Laboratory.

Ghasemi previously has reported developing several new icephobic materials, but he said those, like other existing materials, haven’t been able to completely overcome the problem of ice adhering to the surface, along with issues of mechanical and environmental durability. The new understanding of stress localization allows the new material to avoid that, he said.

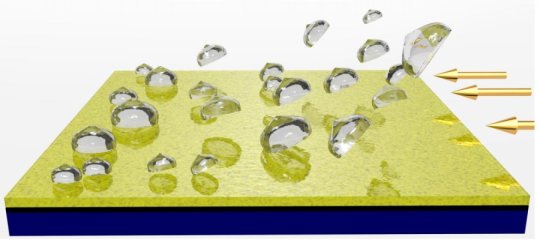

The new material uses elastic energy localization where ice meets the material, triggering cracks at the interface that slough off the ice. Ghasemi said it requires minimal force to cause the cracks; the flow of air over the surface of an airplane acts as a trigger, for example.

The material, which is applied as a spray, can be used on any surface, and Ghasemi said testing showed it is not only mechanically durable and unaffected by ultraviolet rays — important for aircraft which face constant sun exposure — but also does not change the aircraft’s aerodynamic performance. Testing indicates it will last for more than 10 years, with no need to reapply, he said.

Story Source:

Materials provided by University of Houston. Original written by Jeannie Kever. Note: Content may be edited for style and length.

[ad_2]