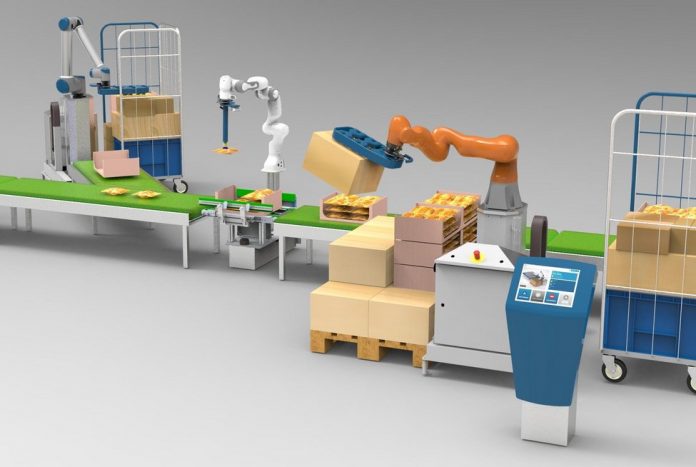

With the rise of e-commerce, robots have become indispensable in distribution centers across the world. However, logistics robots are not as smart and fast as you might think. Because they cannot predict what happens when items are hit or tossed, robots have difficulty placing them on a conveyor belt or in a crate or box in one single rapid movement. People, on the contrary, are very good at exploiting collisions, and are thus extremely fast. There is drawback though: manual work in logistics is often repetitive, poorly paid, and potentially unhealthy due to the lifting of heavy loads. As a consequence, fewer and fewer people are willing to work in such conditions, despite growing market needs. To address this socio-economic challenge, TU/e –together with other two universities, one research institute, and four companies– has started a four-year research project focused on impact-aware robot manipulation in the logistics domain. The EU supports the I.AM. project with a 4.4 million euro grant.

As we all know, robots are extremely good at routine operations. You can program them to pick up objects and place them into a box or on a conveyor belt. The problem is that, because the robots cannot forecast the effect of collisions and are therefore unable to prevent possible harm, these robotics arms need to halt just before they place down or pick up a package, slowing up the whole process. In other words, current robots may be precise and reliable, but they are also quite poor at handling dynamic contact tasks. They fear impacts, instead of exploiting them.

TOSS OR SLAM

People are much better at predicting the consequence of a collision and decide if it could be harmful or not for a given object and themselves. People are therefore a lot faster at handling objects than robots. They are able to put an item on a conveyor belt in one single fast movement, even deciding to toss or slam the item onto the conveyor to speed up the process, without damage. Similar challenges occur when we want to place quickly items in a crate or a box. Not only are people faster at this than robots, they are also much better at filling the container as densely as possible, by quickly pushing objects into it.

Humans are also still the preferred option when unloading pallets, a process that is known in logistics as depalletising. Automatic systems do exist for this, but they are quite expensive and take up a very large space. Even in this context, an impact-aware robot would be a godsend, learning to predict the effect of simultaneous collisions and quickly react to unexpected impact situations via reflex actions.