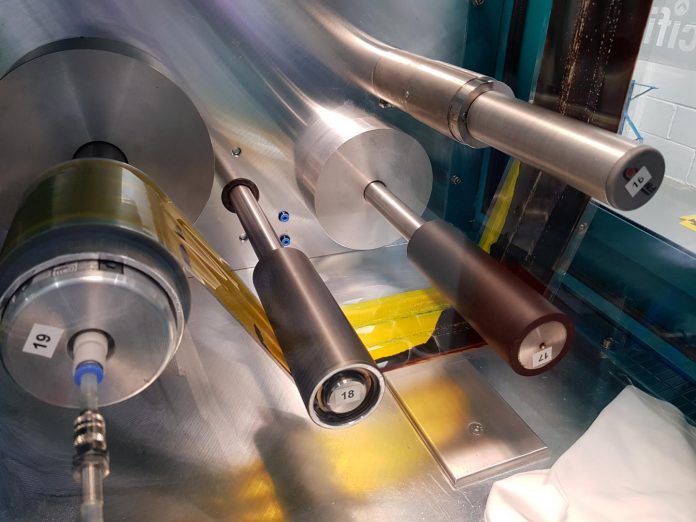

IMAGE: Two-step roll to roll coating of perovskite thin films at Swansea University, where researchers from the SPECIFIC project have achieved record efficiency levels for printed solar cells.

view more

Credit: SPECIFIC/Swansea University

A new study reports the highest efficiency ever recorded for full roll-to-roll printed perovskite solar cells (PSCs), marking a key step on the way to cheaper and more efficient ways of generating solar energy.

A team at Swansea University’s SPECIFIC Innovation and Knowledge Centre, led by Professor Trystan Watson, has reported using a roll-to-roll fabrication method for four layers of slot-die coated PSCs.

The PSCs gave the stable power output of 12.2% – the highest efficiency recorded for four layers of roll-to-roll printed PSCs to date.

A newcomer to the photovoltaic industry, PSCs have gathered remarkable attention from researchers around the globe. With efficiency reaching similar levels to those of silicon photovoltaics (PV), the current market leader, attention has been diverted towards upscaling PSCs.

In contrast to silicon PV, which requires high temperature and high vacuum depositions, PSCs can be solution-processed at a low temperature, which significantly reduces the manufacturing cost.

Low temperature processing makes it possible to use plastic substrates to create flexible solar cells.

The ability to solution-process provides the opportunity to apply various well-developed printing and coating techniques:

- Screen printing

- Inkjet printing

- Gravure printing

- Slot-die coating

- Spray coating

These advantages made it possible for Swansea University researchers to use roll-to-roll manufacturing for four layers of PSCs.

Slot-die coating provides several advantages over the alternatives: it is a pre-metred technique, which means the wet film thickness can be controlled before coating. It is also highly efficient in material usage, with minimal loss of material compared with spray coating or screen printing.

Using the necessary toxic solvents at an industrial scale requires a lot of air handling to stay under the safety limits, which can incur significant and unnecessary expenses. For this reason, an acetonitrile-based system was used. This system has a rheological advantage due to low viscosity and low surface tension, which results in better coatings.

Along with this, a ternary blend of high workplace exposure limit solvents was introduced, replacing chlorobenzene for the deposition of hole transport material. In this research, the PSCs gave the stable power output of 12.2%, which is the highest efficiency reported for four layers of roll-to-roll printed PSCs.

A complete solar cell for a chosen architecture requires coating five layers. In this case, four layers were coated using slot-die coating and the top contact was put on using thermal evaporation. Slot-die coating the fifth (top) contact without destroying any layers underneath has not yet been achieved. Solving this would enable the manufacture of a fully roll-to-roll printed PSC.

Rahul Patidar of SPECIFIC, lead researcher on the project, said:

“Perovskite solar cells aim to increase the efficiency and lower the cost of traditional solar energy generation. They have the potential to be highly efficient and relatively cheap to manufacture, so the aim is to improve fabrication methods for upscaling.

This study signifies the next step towards commercialisation.”

###

The research was published in Sustainable Energy and Fuels.

Notes to editors:

SPECIFIC Innovation & Knowledge Centre aims to reduce carbon emissions from buildings by developing a range of technologies that use solar energy to generate, store and release heat and electricity in buildings. The centre works at all scales from the fundamental lab science to full-scale demonstration on buildings and works with industry partners to bring new technologies to market. SPECIFIC is led by Swansea University and is funded by the European Regional Development Fund through the Welsh Government, Innovate UK and EPSRC.

Website: https:/

Twitter: https:/

LinkedIn: https:/

Swansea University is a world-class, research-led, dual campus university offering a first-class student experience and has one of the best employability rates of graduates in the UK. The University has the highest possible rating for teaching – the Gold rating in the Teaching Excellence Framework (TEF) in 2018 and was commended for its high proportions of students achieving consistently outstanding outcomes.

Swansea climbed 14 places to 31st in the Guardian University Guide 2019, making us Wales’ top ranked university, with one of the best success rates of graduates gaining employment in the UK and the same overall satisfaction level as the Number 1 ranked university.

The 2014 Research Excellence Framework (REF) 2014 results saw Swansea make the ‘biggest leap among research-intensive institutions’ in the UK (Times Higher Education, December 2014) and achieved its ambition to be a top 30 research University, soaring up the league table to 26th in the UK.

The University is in the top 300 best universities in the world, ranked in the 251-300 group in The Times Higher Education World University rankings 2018. Swansea University now has 23 main partners, awarding joint degrees and post-graduate qualifications.

The University was established in 1920 and was the first campus university in the UK. It currently offers around 350 undergraduate courses and 350 postgraduate courses to circa 20,000 undergraduate and postgraduate students. The University has ambitious expansion plans as it moves towards its centenary in 2020 and aims to continue to extend its global reach and realise its domestic and international potential.

Swansea University is a registered charity. No.1138342. Visit http://www.

For more information:

Megan Chick, marketing and communications officer, SPECIFIC project, Swansea University: [email protected]

Kevin Sullivan, senior press officer, Swansea University [email protected]

Follow us on Twitter: http://www.

Find us on Facebook: http://www.

TDnews