Administering medications to children poses unique challenges, especially in resource-limited countries with high infant and child mortality rates. Many drugs are solids or tablets, which are not easily swallowed by children and difficult to dose according to a child’s weight. While liquid and semi-solid alternatives exist for some drugs, many medications lack this option, or become unstable without a reliable cold supply chain. To address these issues, researchers from Brigham and Women’s Hospital and the Massachusetts Institute of Technology developed a new oil-based gel formulation. In a clinical study, the researchers showed that the low-cost “oleogels,” derived from materials already in use by the food industry, can be formulated to be given as fluid, as thickened beverages, and as stiff as yogurt puddings. Additionally, preclinical research demonstrated that oleogels can facilitate drug uptake at levels comparable to or better than solid tablets, while allowing for metered dosages suitable for children. Results are published in Science Advances.

“Most liquid or semi-solid systems are water-based and pose limitations for delivering drugs that cannot be dissolved in water,” said lead author Ameya Kirtane, PhD, of the Brigham’s Division of Gastroenterology and the Department of Chemical Engineering at MIT. “Our system is an oil-based system gel, which makes it compatible with most drugs. This enables the formulation of drugs that were not available in semi-solid or liquid dosage forms and allows patients, especially children, to more easily take their medicine.”

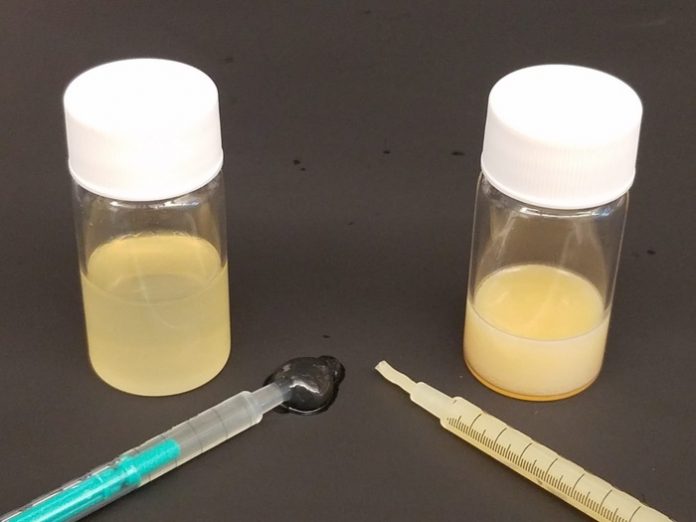

The oleogel system is composed of simple ingredients: a vegetable-based oil (such as cottonseed, safflower, or sesame oil), a gelling agent to optimize viscosity and heat-stability (such as beeswax, candelilla wax or carnauba wax), and a solubilizer that helps the drug dissolve in the oleogel. Thus, the drug-delivery system has an established safety profile and can be easily and widely produced. It does not need to be reconstituted with water and was shown to withstand storage at 40 degrees Celsius (over 100 degrees Fahrenheit), making it ideal for a resource-limited environment.

In a proof-of-concept experiment in pigs, the researchers demonstrated that their oleogel system could successfully deliver four anti-infective drugs (azithromycin, praziquantel, lumefantrine and moxifloxacin), whose chemical properties and functions are wide-ranging. The researchers found that a hydrophilic (water-dissolving) drug like moxifloxacin could be delivered using a slightly adapted oleogel, called an oleopaste. Notably, the route of administration (oral versus rectal) influenced the uptake of the medications, highlighting the importance of optimizing oleogels for each drug of interest.

The research team partnered with the consulting firm Sensory Spectrum to assemble taste panels for evaluating which combinations of oils and gelling agents would be most palatable to patients. They also tailored the packaging of the oleogels to accommodate metered doses.

As a next step, the researchers will conduct a first-in-human trial with healthy adults enrolled at the Brigham to evaluate the oleogel’s efficacy in delivering azithromycin. The researchers emphasize that beyond its suitability for pediatric care in resource-limited settings, the oleogel system could also be useful for older adults, people with gastrointestinal disorders, or for palliative care patients.

“We have a very simple but very elegant solution to administering medications for those with swallowing difficulties,” said corresponding author Giovanni Traverso, MB, BChir, PhD, of the Brigham’s Division of Gastroenterology and the Department of Mechanical Engineering at MIT. “This was an enormous team effort, which included fundamental formulation science, sensory evaluation and dispensing system fabrication and testing, and it was inspired by methods that are recognized and used already within the food industry.”