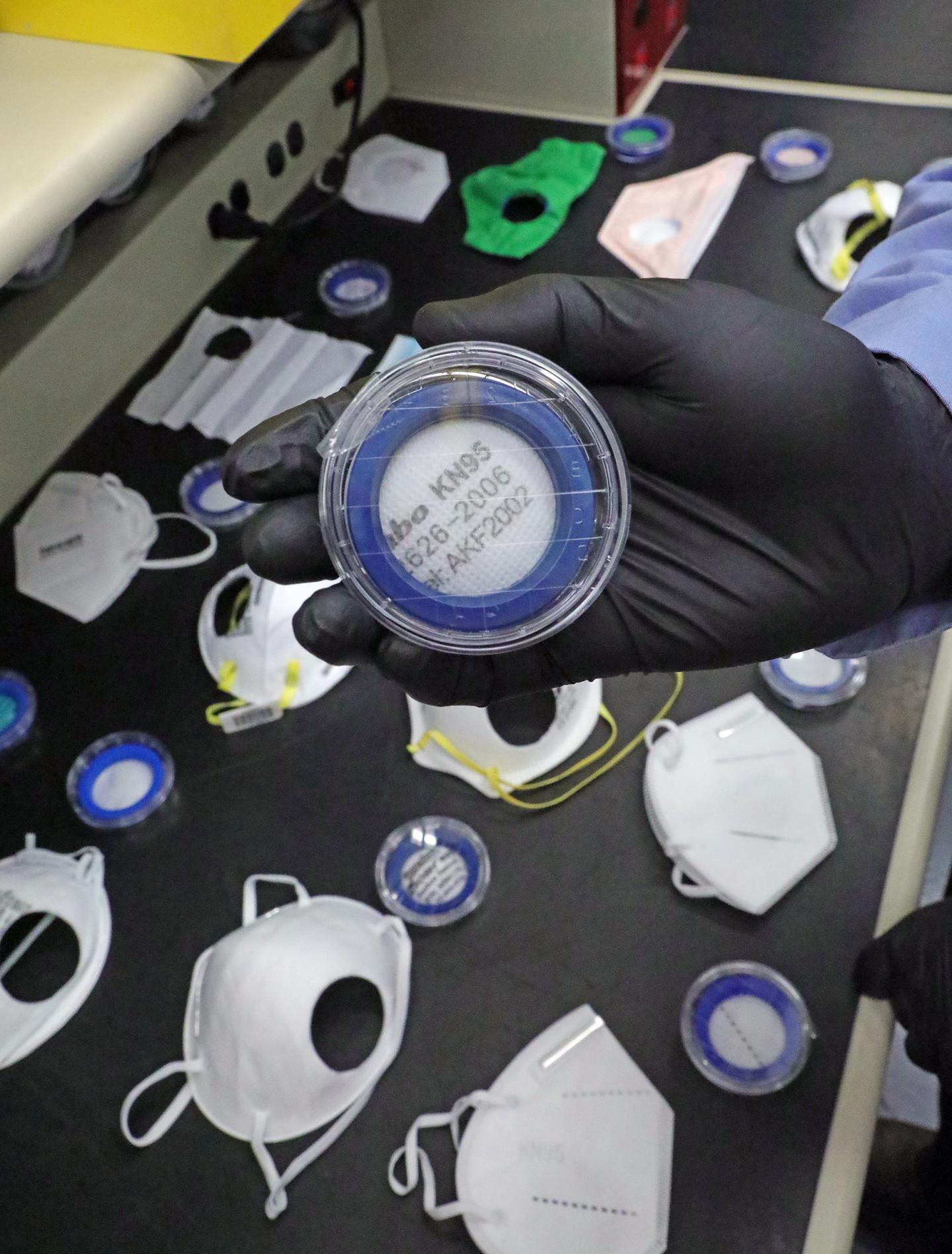

IMAGE: The SwRI Particle Science and Technology Laboratory team is testing N95 and KN95 respirators and surgical masks for quality assurance. Engineers cut out a sample of mask material to evaluate…

view more

Credit: Larry Walther, SwRI

The Particle Science and Technology Laboratory at Southwest Research Institute has expanded its services to include mask testing in response to the COVID-19 pandemic. The testing will help health care and other organizations evaluate respirators, surgical face masks and filtration materials to ensure they meet particle filtration standards.

“A face mask shortage in the United States prompted many organizations to make their own masks or buy masks from international manufacturers for the first time. It is crucial to determine whether these alternatives meet strict standards before they are distributed to frontline health care workers,” said Dr. Imad Khalek, an SwRI senior program manager leading the effort. “We are evaluating mask materials for particle filtration and flow resistance to ensure they can effectively block viral particles, while allowing users to breathe.”

Recent testing at SwRI revealed eight out of the 11 KN95 respirator samples submitted by clients were counterfeit and failed to meet the U.S. standard for filtration efficiency set forth by the National Institute of Occupational Health and Safety (NIOSH). Like the NIOSH-certified N95 respirators, uncertified KN95 respirators manufactured in China are supposed to filter out at least 95% of very small particles. However, once evaluated in the particle lab, the respirators did not perform as expected. While testing uncertified respirators is critical for safety, SwRI is also testing certified brands for additional quality control and assurance.

“It’s important to test samples from known certified manufacturers to ensure masks perform the way they should,” Khalek said. “This also applies to respirators that are decontaminated and re-used due to shortages.”

The laboratory team is offering testing at a reduced price to allow wide accessibility for health care, commercial and government clients who want to quickly evaluate mask samples. SwRI’s laboratory is ISO/IEC 17025-accredited by the American Association for Laboratory Accreditation to calibrate devices that measure particles as small as 10 nanometers in diameter. Before the pandemic, the lab only conducted engine emission particle testing. Khalek says it was a simple transition from emissions to viral particles because they are similar in size. While the mask testing service is now offered at a low cost, the team conducted this work as a community service for several weeks.

“When requests for mask testing started emerging at the height of this crisis, we felt that providing this work pro bono to the community was a critical part of the Institute’s mission to serve the public interest,” said Khalek. “The demand is increasing. So, we are making this service more widely available at a reduced cost.”

The data provided by the lab is not intended to replace precertification requirements for NIOSH and the Food and Drug Administration, the agencies that certify respirators and surgical masks for health care workers. However, the data are in accordance with their standards.

###

Watch a video about this development in near-zero emissions technology at: https:/

Listen to Khalek discuss mask testing on the Technology Today Podcast: https:/

For more information, visit: https:/

Client Service link: https:/

TDnews