Imagine if we could take CO2, that most notorious of greenhouse gases, and convert it into something useful. Something like plastic, for example. The positive effects could be dramatic, both diverting CO2 from the atmosphere and reducing the need for fossil fuels to make products.

A group of researchers, led by the University of Toronto Ted Sargent group, just published results that bring this possibility a lot closer.

Using the Canadian Light Source and a new technique exclusive to the facility, they were able to pinpoint the conditions that convert CO2 to ethylene most efficiently. Ethylene, in turn, is used to make polyethylene—the most common plastic used today—whose annual global production is around 80 million tonnes.

“This experiment could not have been performed anywhere else in the world, and we are thrilled with the results” says U of T PhD student Phil De Luna, the lead researcher on this project.

The Science

At the heart of this work is the carbon dioxide reduction reaction, wherein CO2 is converted into other chemicals through the use of an electrical current and a chemical reaction, aided by a catalyst.

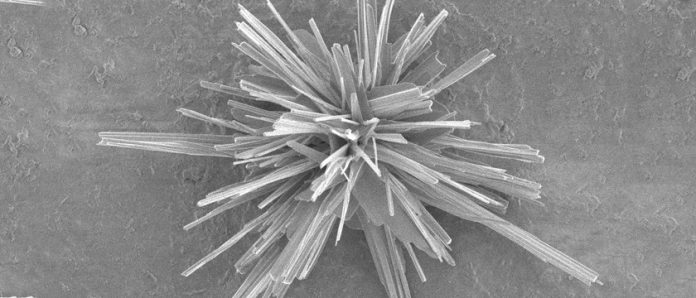

Many metals can serve as catalysts in this type of reaction: gold, silver and zinc can make carbon monoxide, while tin and paladium can make formate. Only copper can produce ethylene, the core component of polyethylene plastic.

“Copper is a bit of a magic metal. It’s magic because it can make many different chemicals, like methane, ethylene, and ethanol, but controlling what it makes is difficult,” says De Luna.

That is precisely what the team’s results address, however. They were able to design a catalyst and pinpoint the ideal conditions to maximize ethylene production, while minimizing the methane output to nearly nothing.

Paired with carbon capture technology, this could lead to an incredibly green production mechanism for everyday plastics, meanwhile sequestering harmful greenhouse gases.

“I think the future will be filled with technologies that make value out of waste . It’s exciting because we are working towards developing new and sustainable ways to meet the energy demands of the future,” says De Luna.

Innovative techniques and serendipity

A unique piece of equipment developed by CLS senior scientist Tom Regier made it possible for the researchers to study both the morphology, or shape, and the chemical environment of their copper catalyst throughout the CO2 reduction reaction, in real time.

“This has never been done before,” says PhD student Rafael Quintero-Bermudez, the paper’s other first co-author. “This unique measurement allowed us to explore a lot of research questions about how the process takes place and how it can be engineered to improve.”

By identifying the precise conditions that maximize ethylene production during the reaction, it is possible to engineer a catalyst to meet those conditions.

Quintero-Bermudez and De Luna were approaching the end of their allotted research time at the CLS when the key results came in. After countless hours of work, and many failed attempts, the experiment worked.

“We were about to give up, but when the results came in, they were so good we had to sit down. Really beautiful results,” says Quintero-Bermudez.

Regier was equally pleased with the work.

“We are constantly working to develop more and better tools for the research community to use. It is rewarding when you see the tools being used to solve important problems with significant applications,” says Regier.

The quality of the results speaks for itself.They were among the first research to be published in the brand-new Nature family journal Nature Catalysis.